I first visited China about 18 months in to starting Rheign. The plan was to go to China to visit the two factories I was using at that point plus visit a few other ones to try and explore other options for manufacturing. I was also visiting one of the factories to do some quality control. I was having soft-shell gilets made and they were almost complete so I wanted to visit this factory to go through and randomly check them to make sure they were ok.

To begin with I was flying to Hong Kong and then getting the train into China for my trip. In order to do this I needed a visa to visit China which wasn’t the simplest or cheapest things to do! Previously, I was able to visit the Chinese embassy in Edinburgh and obtain the visa the same day, however, they have changed this and it takes longer now. The last visa I got cost about £200 plus you have to have letters from the factory stating that they are inviting you to visit, how long you will be there and the purpose of the visit. It’s quite a strict process and is something to be done well in advance!

The first visit I made was to a potential new factory. Before my visit I had sent out one of the half zips I had designed to get them to make another sample – so I could check the quality and design. They picked up from my hotel and we drove about an hour to the factory in Guangzhou. As this was the first time I had ever done anything like this it was pretty daunting! Sitting in front of three individuals I didn’t know trying to talk about samples, quality, minimum orders, lead times etc to do with a company I had only been running for 18 months and as I didn’t speak the language we were doing it all in English. Their English was good but imagine trying to mix in a Scottish accent – it didn’t make for the easiest conversation! The hardest part I found was getting across everything I wanted to say. Once you start talking about different fabrics, orders, designs etc its quite hard to keep up and keep on point and come away with a decision or outcome about things. But it was great to meet the people I was planning to work with and I am now good friends with them!

Sandy, Lisa, Catherine

Visiting the factories is quite overwhelming because you are so aware that there is a lot to go through, get across and discuss and you only have a few hours in which to do it – and you have to make sure you are writing down the right things and remembering all points! To begin with I tend to try and discuss the orders that have either been delivered and were there any issues or deal with an upcoming orders. The benefit of meeting face to face is you can discuss any issues much easier than via email. If they don’t know who you are, what your business is about and what values are important to you – i.e. quality and workmanship then how can anything ever be fixed. The biggest issues with manufacturing is lack of communication. The biggest issues with quality come when you do not convey exactly what you want. How is somebody to know that a certain aspect is not acceptable if you do not tell them? And equally meeting face to face allows the factory to speak to you and explain maybe certain processes that are difficult to meet or cause issue for them.

The second visit I did was to another potential new factory who made sportswear. This time I got the train from Guangzhou to Guangdong where I was to meet one of the sales women. When I arrived there was no one there only a big group of men trying offering taxis! It was difficult to just phone the factory and they couldn’t understand me even if I got through but eventually someone turned up thankfully!

This visit was more about whether they felt they could make the half zip top I had with me and to discuss pricing and minimums. At this factory we had our meeting in their showroom – showrooms at the factories are amazing!! There is so much product, designs, colours, fabrics it is so difficult to know where to start! Your mind starts running with what different ideas you can do and trying to take photos of the right things to remember when back home is quite difficult. You get back and wish you had looked at so much more!

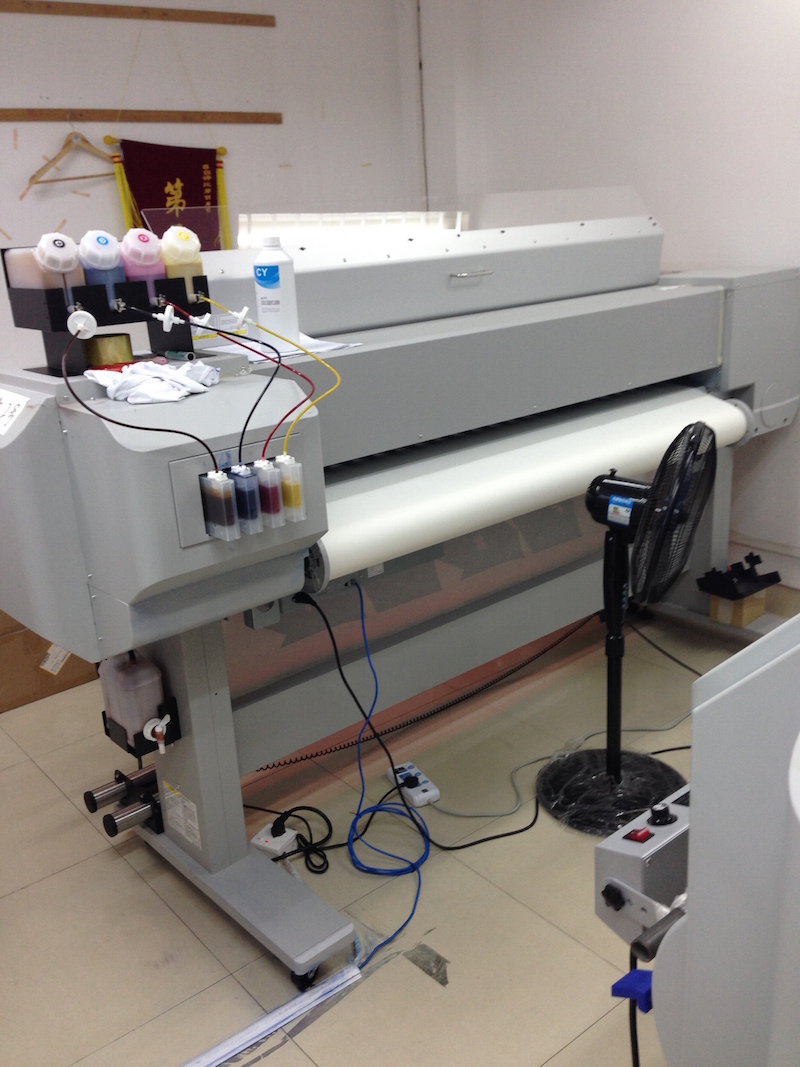

The machine for sublimation printing

The final visit was in Fuzhou where I had to get an internal flight from Guangzhou. This was to a factory where I was having an order of soft-shell gilets made. I wanted to go and do some quality checks to make sure all was going to go smoothly. Working on the factory floor was so interesting. It was hot, large and busy!! Like most factories the world over. I remember being there and feeling that was the first time I really had to step up confidence, take control of what I needed to do and get on with it. Nobody else was there to help me, only I knew what I wanted to get out of this visit and given the fact I was thousands of miles from the UK I didn’t have a second chance to just pop back next week to sort anything out! It was a good visit and again it was so useful to meet the people I was working with.

This post I guess is more me telling the story of visiting China & the factories but it might give a bit of an insight into the factories and how they work.

By far and away the biggest single thing taken from this trip was meeting the people I was/am working with. It makes things so much easier. Whilst this is not always possible, if you are having goods manufactured anywhere eventually you will want to/need to meet them. You can convey so much more face to face than you ever will over email. I got, out of that first trip, something you will never truly get by just communicating online – trustworthy, honest and reliable relationships. This is worth everything.

Final day back in Hong Kong